MES - HYDRA

Shop Floor Data (BDE)

HYDRA BDE collects data, evaluates the data and then creates statistics with the supplied information

Machine Data Collection (MDE)

With the help of HYDRA MDE you can monitor your machines in real time, and react immediately in the event of malfunctions, or analyze the situation retroactively and thus optimize machine runs in the long term.

Shop Floor Scheduling (HLS)

The shop floor scheduling tool enables realistic detailed planning based on actual capacities and a proactive, responsive production control, which is faster and more effective than a centrally organized PPS or ERP system.

Dynamic Manufacturing Control (DMC)

With HYDRA DMC, you can integrate your line control system seamlessly into your MES and also indirectly into the higher-level ERP system.

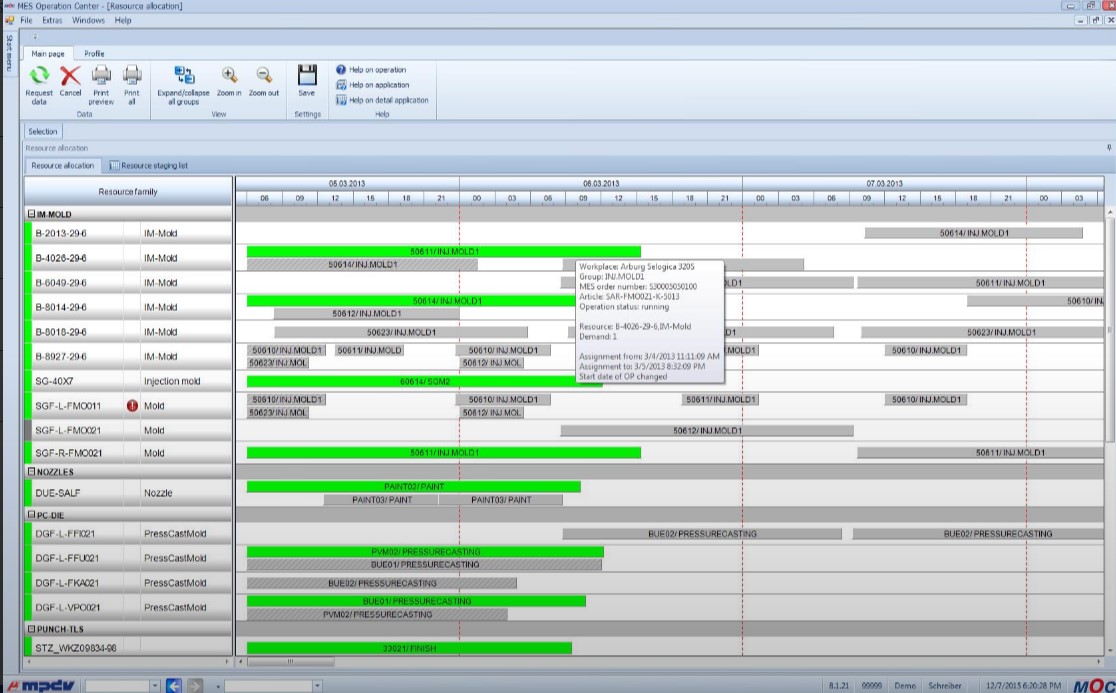

Tools & Resource Management (WRM)

With HYDRA WRM you can efficiently manage & plan tools and resources. It also monitors your tools & schedules servicing and preventive maintenance.

Premium & Incentive Wages (LLE)

HYDRA LLE provides you with reliable and consistent data to calculate incentive pay for your employees, as integrated HYDRA MES applications serve as the foundation for the data.

Personnel Time Management (PZW)

HYDRA PZW supports you in the implementation of today's working time agreements and different types of remuneration and organization.

Material & Production Logistics (MPL)

HYDRA MPL was develope to control material flows and monitor material stocks in production.

Tracking & Tracing (TRT)

HYDRA TRT collects all relevant data involved in production. This data is stored and archived according to customer-specific requirements. This means that data is available at any time for evaluations tailored to your needs.

Energy Management (EMG)

HYDRA module Energy Management (EMG) effectively support the detailed recording, demand oriented monitoring & systematic reduction of your energy consumption, also consumption analysis, and energy management.

DNC & Configuration Data (DNC)

HYDRA DNC transfers data online via networks or data interfaces from and to the machines. So, it can reduces unnecessary sources of error.

Process Data Collection (PDV)

With HYDRA PDV you can collect and manage process data of any type. The analysis of the recorded data is also part of the functional scope.

Personnel Scheduling (PEP)

HYDRA PEP allows personnel scheduling depending on the amount of orders and considering qualification and availability of staff with integrated detailed planning.

Access Control (ZKS)

HYDRA ZKS enables you to control and monitor authorized access of employees and visitors.

In Production Inspection (FEP)

Supports inspection planning, operator self-testing and determination of the usage decision.

Incoming Goods Inspection (WEP)

By performing systematic WEP, quality related problems caused by suppliers are identified before they reach your production. HYDRA WEP also offers an assessment management for supplier evaluations.

Complaint Management (REK)

In addition to processing external complaints initiated by the customer, the HYDRA module complaint management (REK ) uses recorded quality data, including the causes of defects, to automatically trigger internal complaints.

Test Equipment Management (PMV)

The HYDRA module PMV ensures that the required equipment is available in sufficient numbers and equipemnt is in adequate condition.

Failure Mode & Effect Analysis (FMEA)

HYDRA FMEA supports manufacturing companies in providing the required quality of processes and products in the run-up to production.

Time & Attendance (PZE)

HYDRA supports the implementation of today's working time agreements and different types of remuneration and organization.

SEE MORE INFO AT www.mpdv.com